register for newsletter

get latest company news

+86 18359733285

Everything You Need to Know About The dtf printing

An increasing number of businesses are switching to dtf printers, contributing to the printing industry's recent boom.

To that end, you may be wondering, "What is DTF printing, what is a dtf transfer, and why have I been hearing about it everywhere? In this context, "DTF" is a form of heat transfer that has become popular with garment decorators. How is it dissimilar from direct-to-garment printing (DTG) and Heat Transfer Vinyl?

In order to obtain ease, convenience, and consistency in performance with a vast array of colors, DTF Printer is ideal. Moreover, DTF Printers are now dependable and inexpensive machines.

Now, let's get down to brass tacks and see what benefits direct to film printer offers.

Introduction to DTF Printing:

Direct-to-Film printing, also known as DTF printing, is a process in which a graphic printed onto a piece of film with various colored inks is applied to an apparel item. This pre-printed film is binded to the garment through heat and pressure from a heat-press machine. This creates a long-lasting and detailed graphic that can be placed on an array of garments.

Direct-to-film (DTF) printing is a heat-transfer based print process. The process begins by printing designs onto a transfer film, which is then covered with a thermo-adhesive powder and transferred with a heat press to the final substrate.

The Process

DTF printing starts with the film being made on a DTF printer. This printer uses a thick PET film that ensures for better transferring characteristics. The ink used for these printers are in the typical CMYK (cyan, Magenta, Yellow & Black) pigment but also has the addition of white ink. The white ink plays a significant role in the creation of the dtf film as it is the foundation that the colored pigments get placed on.

Once the film is created it is ready to be applied to a garment. We use an in-house heat press machine to adhere these films to the garments. Each garment type will require a different variation of temperature, time, and pressure to ensure the DTF film is properly applied. After pressed onto the item, a clear backing can be peeled off of the film to complete the process!

Understanding the Concept of DTF Printing

DTF printing is a process where designs are printed onto a thin film and then transferred onto various plain t shirt wholesale. Unlike other printing methods, DTF printing doesn't require a separate transfer paper or special inks. Instead, it uses a combination of digital printing technology and heat to create high-quality prints. The designs are first printed on a transparent film using specialized DTF printers, and then heat is applied to transfer the design onto the custom cotton Polo shirts. This direct transfer process eliminates the need for complex steps and simplifies the overall printing process.

Benefits of DTF Printing

DTF printing offers several advantages. Firstly, it allows for high-resolution prints with vibrant colors and fine details. The direct transfer process ensures that the designs are accurately reproduced on various substrates, including fabrics, plastics, and metals. DTF printing also offers excellent T-shirt styling options with durability and washability. It makes a great ideal for items such as clothing and accessories. Additionally, it enables quick turnaround times and cost-effective production, making it a viable option for both small-scale and large-scale printing projects.

Applications and Industries Utilizing DTF Printing

DTF printing has found applications in a wide range of industries, thanks to its versatility and capabilities. The t shirt wholesale outlet industry utilizes DTF printing for customizing clothing items, including t-shirts, hoodies, and hats, with intricate designs. It is also popular in the promotional products industry in bulk T-shirt purchases.

Step-by-Step Guide to DTF Printing Process

Follow this step-by-step guide to learn the printing process and try it on your favorite wholesale tank tops for printing.

1- Prepare the Design;

2- Set up the DTF Printer;

3- Load the Film;

4- Print the Design;

5- Apply Adhesive Powder;

6- Shake Off Excess Powder;

7- Cure the Adhesive;

8- Transfer the Design;

9- Apply Heat and Pressure;

10- Peel off the Film;

11- Post-Processing.

Equipment and Materials Required for DTF Printing

- DTF printer

- Transparent film

- Heat press machine

- Substrates

- Design software

JINGTONG provides one-stop solutions for DTF Printing

Preparing Artwork and Designs for DTF Printing

Before starting the DTF printing process, it's essential to prepare the artwork and designs properly. Besides, pre-order garments from wholesale t-shirts bulk supplier to eliminate any false print. This includes creating or importing high-resolution designs into a digital design software. Ensure that the designs are in the correct format and color profile suitable for printing. Adjust the design dimensions according to the desired size of bulk hoodies for printing. It's also crucial to consider any necessary adjustments for color vibrancy and saturation, as the transfer process may affect the final appearance. After preparing the designs, you can print them onto the transparent film using the DTF printer to initiate the DTF printing process.

Benefits and Drawbacks of Using a DTF Printer

Is a Direct-to-Film Printer a good investment, then? Let's begin by weighing the benefits and drawbacks of this groundbreaking innovation in printing technology.

PROS

It doesn't need any special preparation.

It's versatile enough to be used on a wide variety of materials and fabrics.

It will still have some of the texture of the material it was printed on. The fabric will have great wash resistance after printing.

Compared to other printing technologies, like DTG, this one is much easier and faster to implement.

CONS

When compared to subliminal printing, the printed area is slightly more obvious.

When compared to sublimation printing, the colors could be more vivid.

Choosing the Right Direct To Film Printer

Selecting the appropriate direct to film (DTF) printer is an important aspect for achieving high-quality prints on oversized t shirt wholesale. Consider factors such as printing requirements, budget, and desired features. It's essential to choose a reliable supplier like Jingtong Industry that offers excellent customer support and a track record of performance.

Factors to Consider When Selecting a DTF Printer

Several factors should be taken into account when choosing a DTF printer. Firstly, assess the printing volume and speed required for your specific. Consider the type of top 3 shirts you'll be working with and ensure compatibility with the printer. Evaluate the print quality and resolution capabilities. Additionally, factor in the cost of consumables, maintenance, and overall investment in the printer.

Just have a look at Jingtong Industry DTF Printers.

Features and Specifications to Look for

When evaluating DTF printers, there are key features and specifications to consider. Look for printers with high-resolution printing capabilities to ensure sharp and detailed prints. Check the printer's color management system for accurate color reproduction. Consider the printer's connectivity options, user interface, and ease of use. Take note of the printing width and media compatibility to ensure it meets your desired printing requirements.

dtf transfer printing Instructions

The white ink layer is produced at the same time as the colored inks, which is a major benefit of this method. As a result of this, it's a convenient replacement for time-consuming approaches like using white toner.

If you're using DTF, you should know that eps, PS, pdf, BMP, tif, jpg, png, and PSD are all acceptable file types for printing your designs.

Troubleshooting Common Issues in DTF Printing

When encountering issues in DTF printing, it's important to identify and address them promptly. Some common problems include poor ink adhesion, image quality issues, and printer malfunctions. To resolve ink adhesion problems while printing, adjust curing settings, use recommended ink and substrates, and consider pre-treatment if needed. Blurry prints can be improved by adjusting print resolution and ensuring proper placement of the t-shirts. Color inaccuracies can be addressed through printer calibration and using color management tools.

Nevertheless, regular maintenance, such as cleaning print heads, knowing how to distress a t-shirt, and checking ink flow, helps prevent problems. In case of printer errors, updating firmware, power cycling, and contacting technical support may be necessary. Following manufacturer guidelines and seeking professional assistance when needed can help overcome these challenges.

Identifying and Resolving Ink Adhesion Problems

Issue # 1: Poor ink adhesion, leading to smudging or flaking.

Solution # 1: Ensure proper curing by adjusting heat and pressure settings. Use recommended ink and substrate combinations and try not to ruin. Pre-treat substrates if necessary for better ink adhesion.

Issue # 2: Ink bleeding or spreading beyond the desired print area.

Solution # 2: Check ink viscosity and adjust accordingly. Ensure proper drying time between layers. Use appropriate print settings to control ink flow.

Dealing with Image Quality Issues

Issue # 1: Blurry or distorted prints.

Solution # 1: Check the print resolution and adjust settings for optimal clarity. Ensure the T shirts are flat and properly positioned. Clean the printer heads and perform maintenance regularly.

Issue # 2: Color inaccuracies or inconsistent color reproduction.

Solution # 2: Calibrate the printer to ensure accurate color output over. Use color management software and profiles. Check ink levels and replace cartridges if needed.

Maintaining and Calibrating DTF Printers for Optimal Performance

Issue # 1: Printer jams or misfeeds.

Solution # 1: Clean the printer rollers and ensure they are free from debris. Adjust the paper or film alignment. Use proper tension settings for smooth feeding.

Issue # 2: Uneven ink distribution or banding in prints.

Solution # 2: Perform regular maintenance, including cleaning the print heads and ensuring proper ink flow. Calibrate the printer to achieve even ink distribution all over t-shirts.

Issue # 3: Printer errors or malfunctions.

Solution # 3: Update printer firmware and drivers. Reset the printer and power cycle if needed. If this issue is not resolved then shirts can be ruined by ink all over the body. Contact technical support for further assistance.

Regular maintenance, proper calibration, and following manufacturer guidelines can help prevent ink bleeding over shirts. Moreover, it can resolve common issues in DTF printing. Troubleshooting techniques may vary depending on the specific printer model and ink system. Refer to the printer's manual or seeking professional support is recommended when encountering persistent problems.

What The Future Holds?

As one of the most rapidly expanding avenues for embellishing garments, it's a fad that would benefit from early adoption. It also provides more options, as you can print designs for both yourself and others.

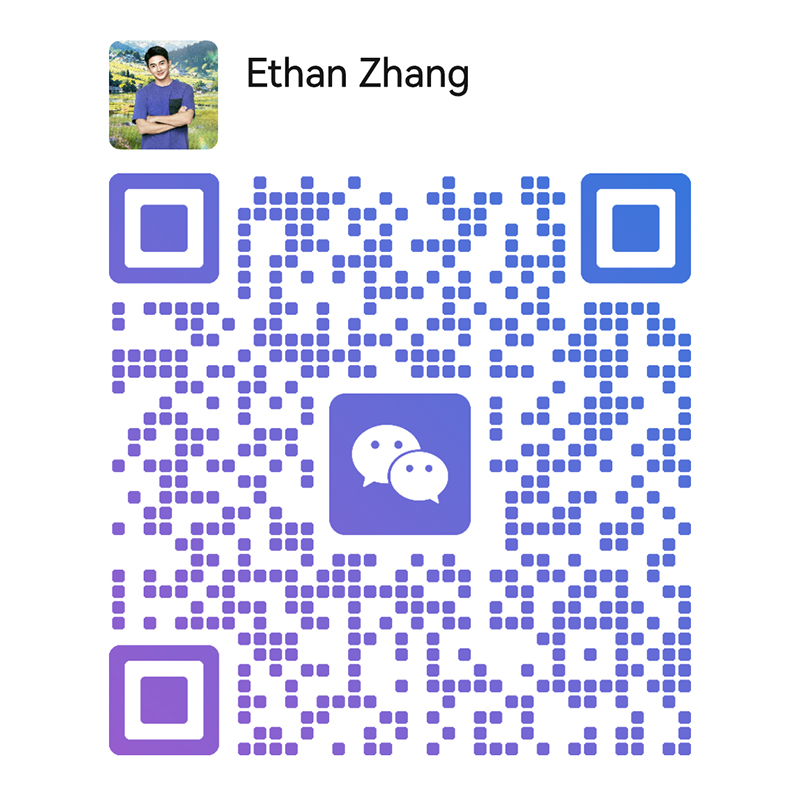

Scan To Wechat