45cm Personalised T Shirt Transfers Paper Double-Side Hot Cold Peel DTF Film Roll Wholesale

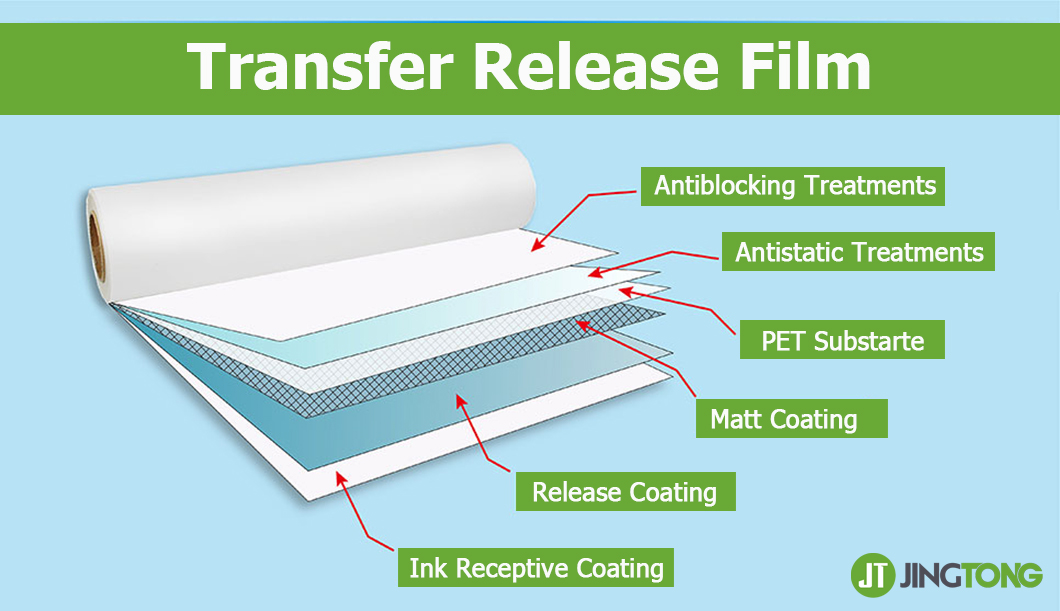

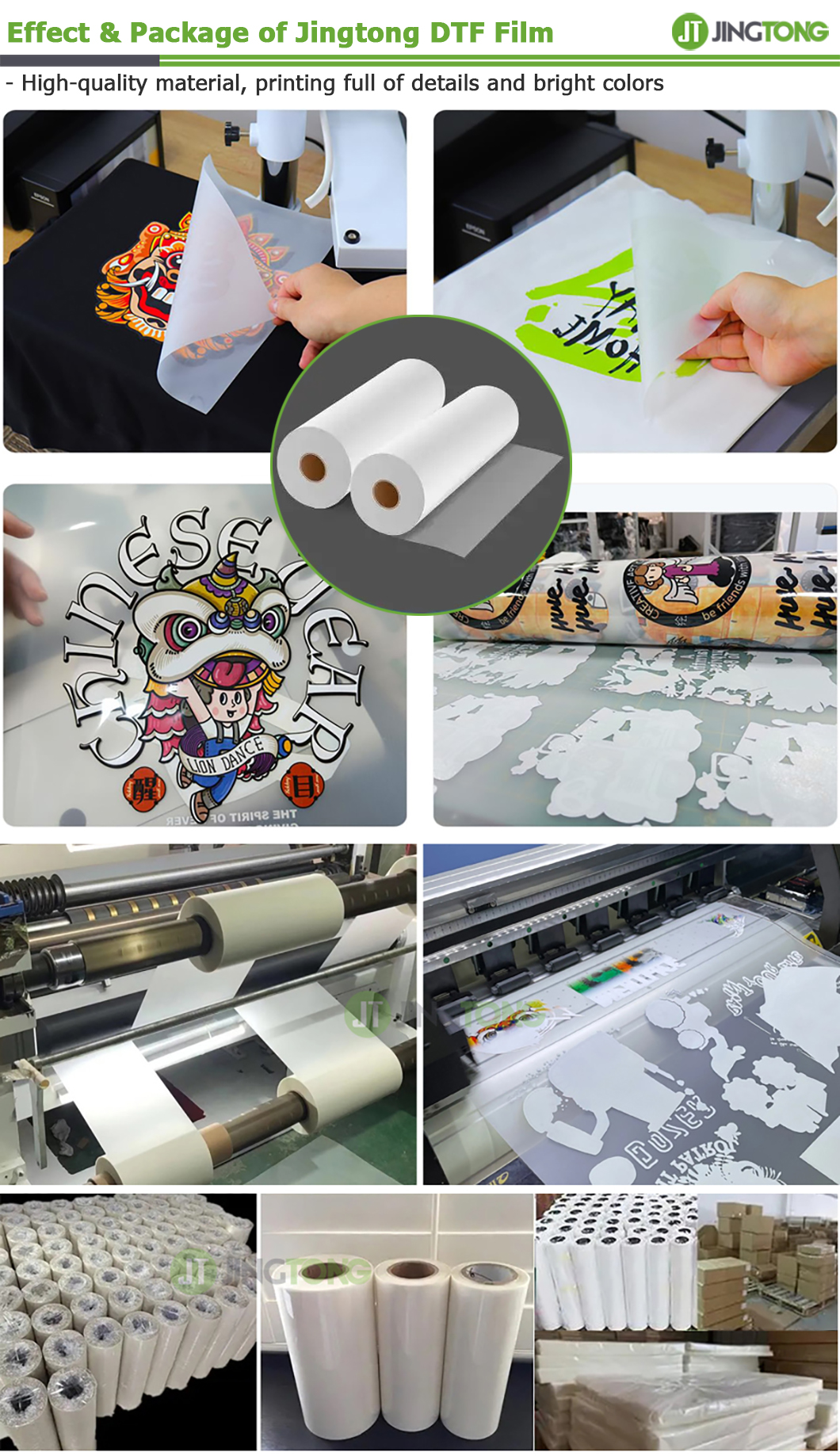

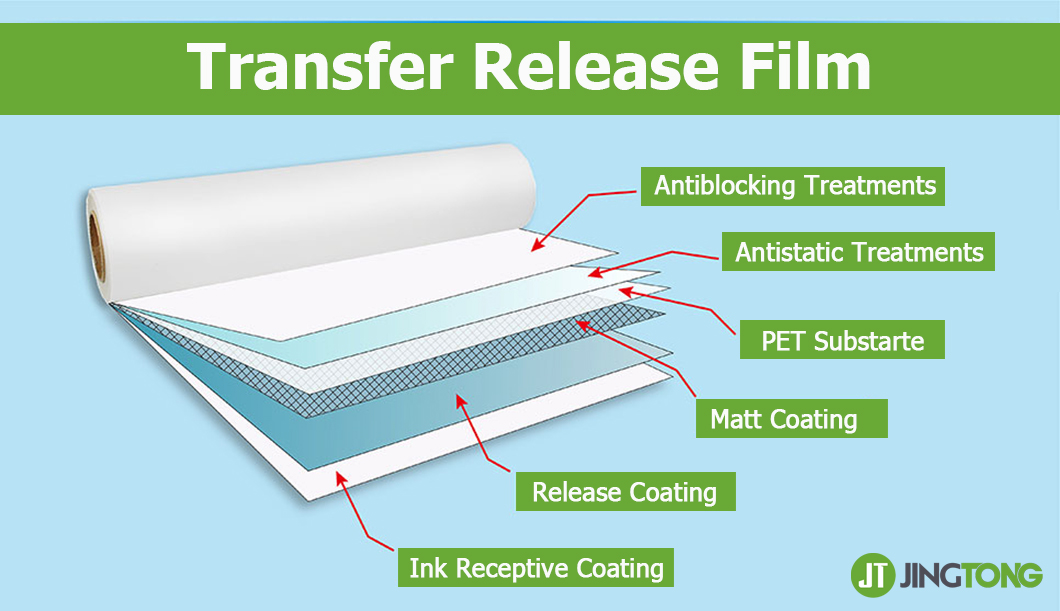

Jingtong Industry 45cm Personalised T Shirt Transfers Paper Double-Side Hot Cold Peel DTF Film Roll have exceptional ink receptivity and anti-static and anti-blocking properties. Our PET film is specially designed for DTF printers. Non-slip, no oil, no sticking, uniform coating, and easy to peel off. In addition, the final image can be enhanced with a matte, glitter, or shiny effect in hot or cold peel versions, as well as a super soft touch effect.

Features

Jingtong DTF Transfer Film is used in the direct to film printing process. These films are different from those used for screen printing and have better transmission characteristics.

DTF film is available in cut sheets and rolls. It is based on the type of peel after transfer. Depending on the temperature, the film can be either a hot-peel or cold-peel film.

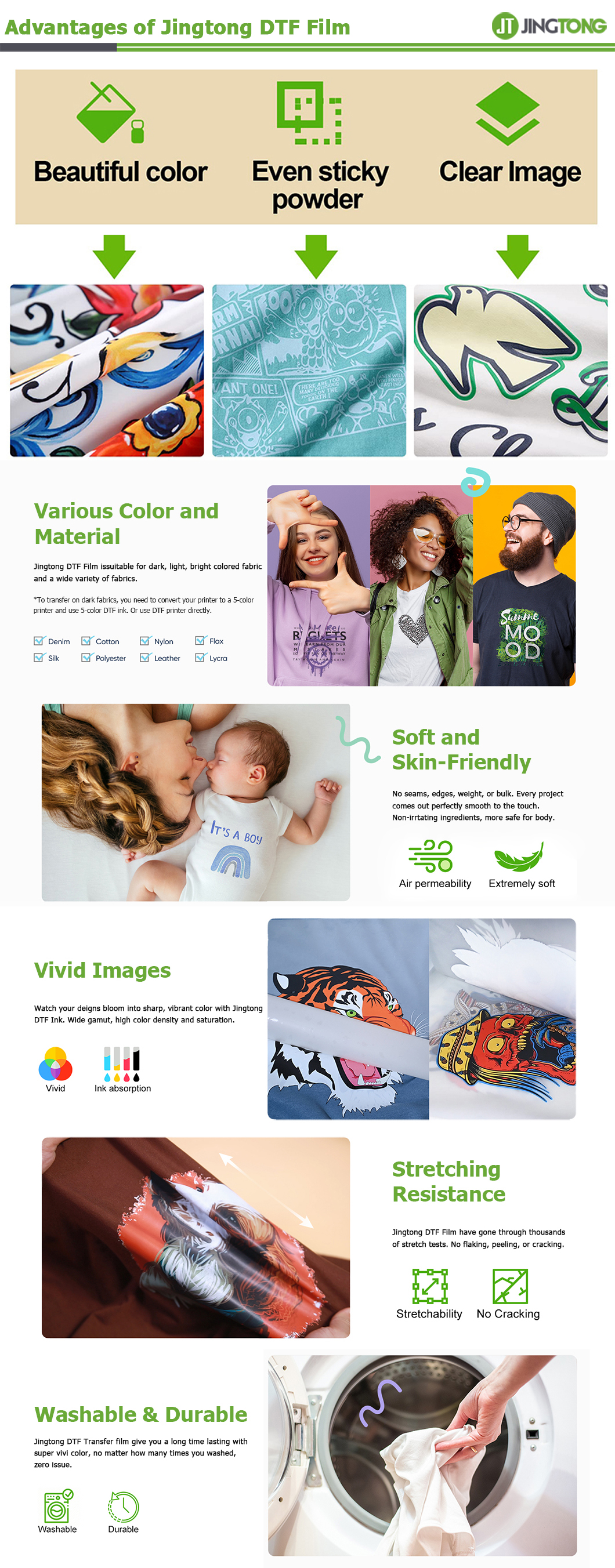

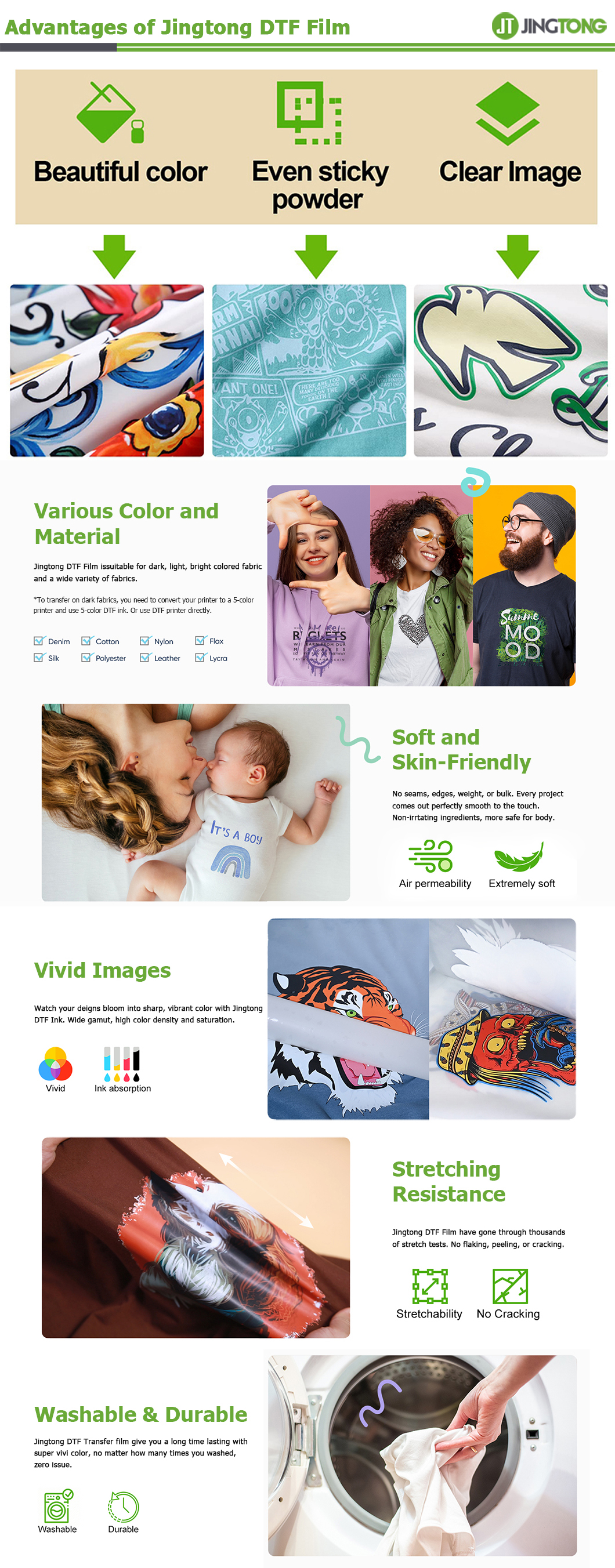

Advantages

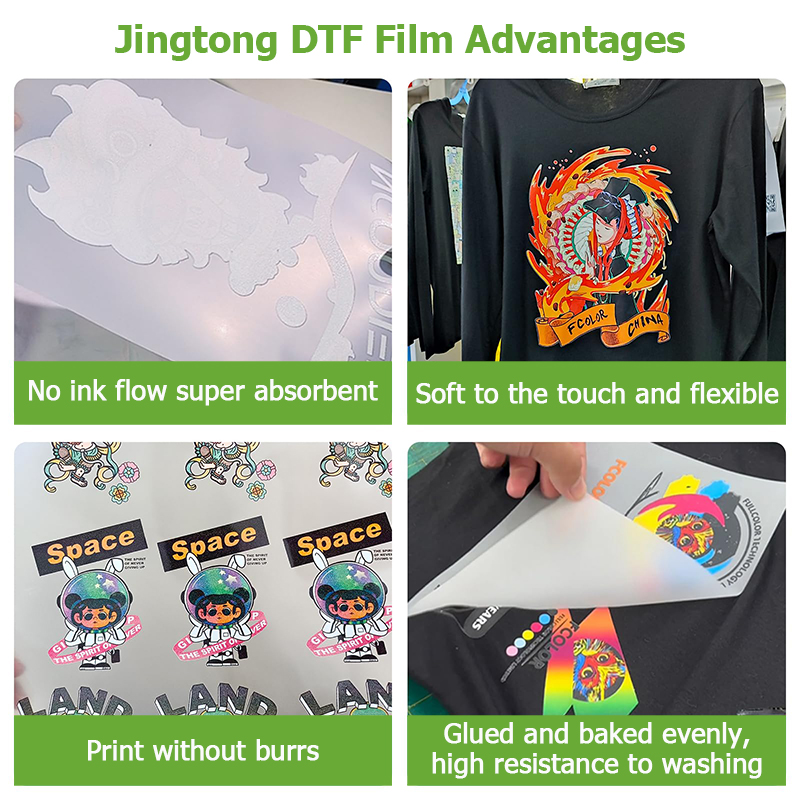

- The surface is smooth and clean.

- Strong ink absorption capacity, thick ink absorption layer.

- The color of the pattern is realistic and complete, no halo.

- Excellent physical and mechanical properties.

- Low shrinkage, high temperature resistance.

- Small thickness tolerance, good matte, low heat shrinkage, good release.

- Two steps of printing and transfer, easy cooperation , save time and cost .

Added Values:

Multi-coating process

Antiscratch properties

Hot and cold peel versions

Glossy, matt and glitter finishings

Breathability

Long lasting, no fading

Low heat shrinkage

Strong ink absorption capacity

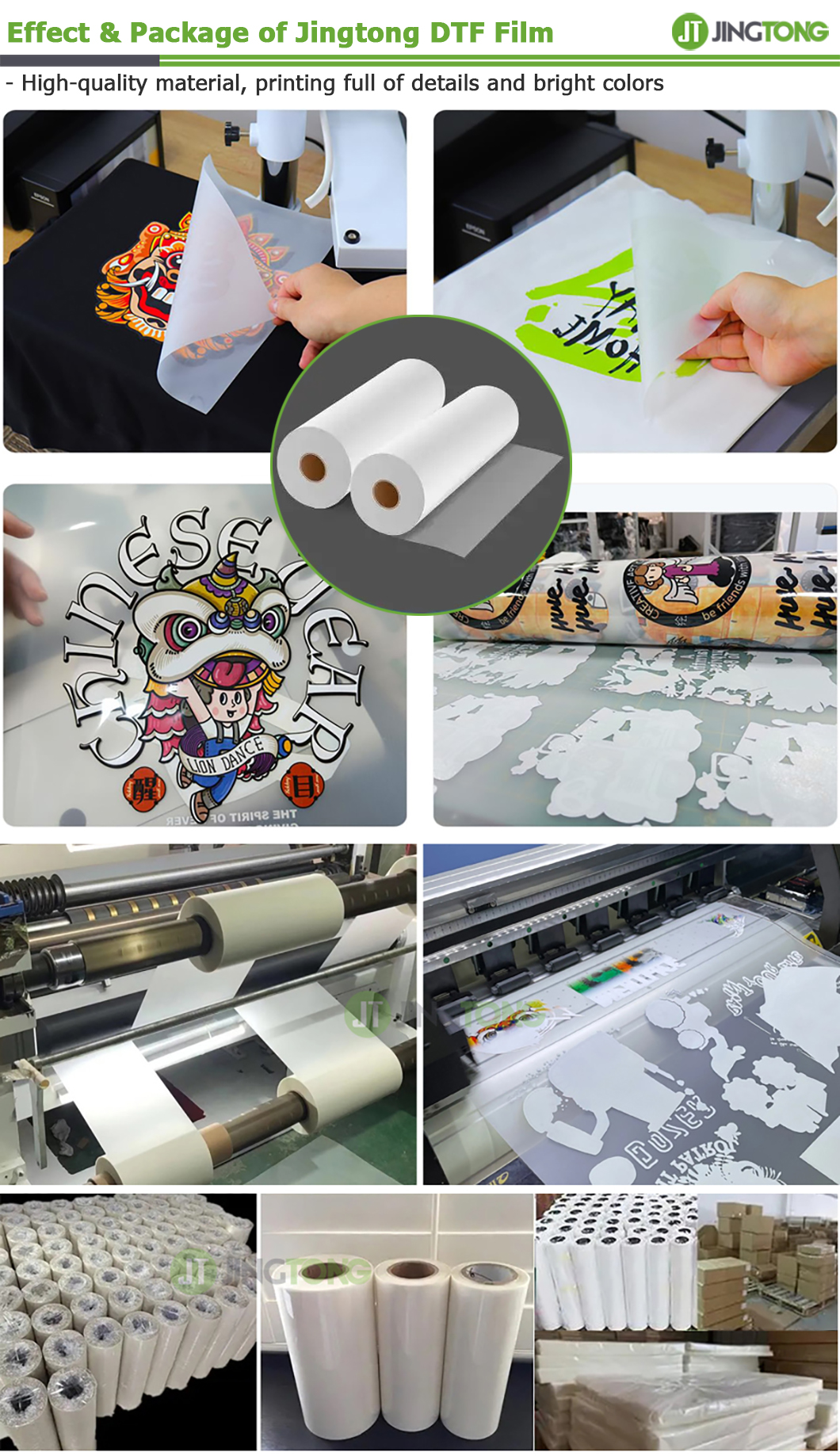

Specification of Jingtong DTF Film

| MODEL | SIZE | CORE | THICKNESS | PACKAGE |

| DTF Film 30 D/S | 30cm * 100m | 2inch/3inch | 38μm, 50μm, 75-130μm | 4rolls/carton |

| DTF Film 60 D/S | 60cm * 100m | 2inch/3inch | 38μm, 50μm, 75-130μm | 2rolls/carton |

| DTF Film 120 D/S | 120cm* 100m | 2inch/3inch | 38μm, 50μm, 75-130μm | 1rolls/carton |

| DTF Film A3 D/S | A3 | / | 38μm, 50μm, 75-130μm | 200pcs/carton |

| DTF Film A4 D/S | A4 | / | 38μm, 50μm, 75-130μm | 200pcs/carton |

| Custom Width and Length, Single Side/Double Side, Glossy/Matte Finish are all available. |

| Transfer Temperature: | 130-160°C |

| Transfer Time: | 8-15s |

| Type: | Cold and hot peel-off application |

| Application: | T-shirts

Sportswear

Fashion

Workwear

Home Decoration

Textile Goods, etc |

Working Conditions of DTF Film

About Printing:

The image side is wound around the outside of the paper. Allow the printing ink to dry before transferring.

Testing Condition:

Ink-load: 400% Max; Transfer Temperature: 130-165ºC; Transfer Time: 8-15 seconds

About Storage:

In order to protect unused transfer film, it is recommended to store it in its original packaging, in the poly bag, at 68°F-82°F (20°C-28°C) and 40-60% RH.

About Washing:

Washing in low temperatures, about 30-40 ºC (86-104 F) or even at a cold wash and use medium washing cycles (600-800 rpm).

FAQ of Jingtong DTF Pet Film

Q: Can DTF film be reused more than once?

No. The coating on the DTF film is used up during the printing and transfer process. If you print again, the ink will flow away instead of sticking.

Q: Is the DTF film anti-fading?

DTF printing is durable. DTF ink adheres well to fabrics, allowing designs to withstand multiple washes and sun exposures without fading or cracking.

Q: How to Choose Best DTF Film?

Usually, consider the following 6 factors to choose the right DTF film:

1. Ink-absorption capacity

2. Coating layer

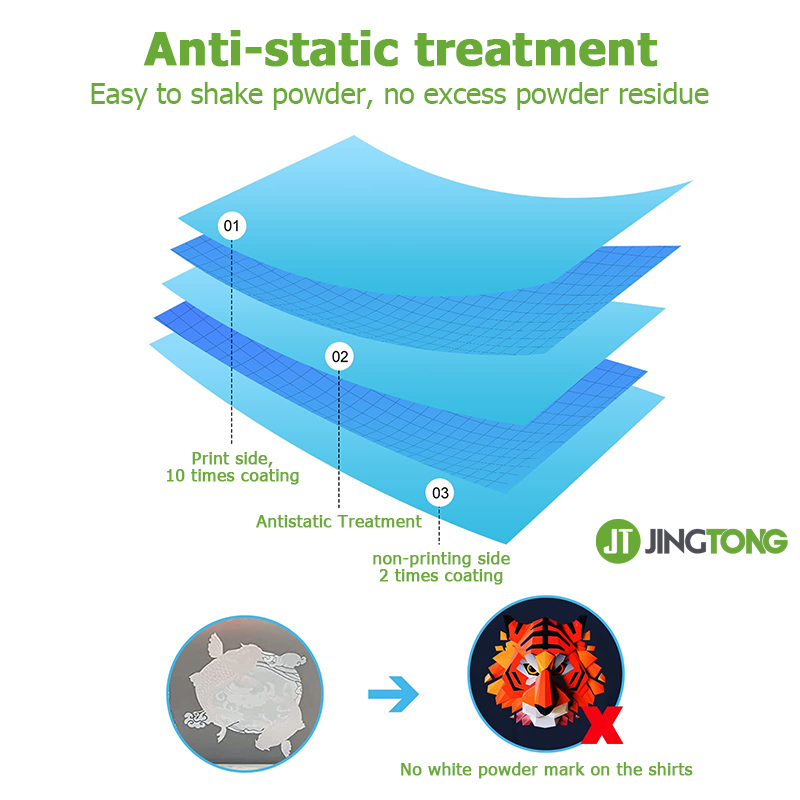

3. Powder shaking effect

4. Release effect

5. Storage capacity

6. High temperature resistance

Q: What is DTF PET Film?

DTF film is produced on the base layer of the PET material, coated with release layer and ink-absorption layer. High quality film adds back coating to realize anti-static electricity and anti-adhesion continuous treatment.

Q: Hot Peel vs. Cold Peel Film, Which is Really Better?

DTF hot peel film is ideal for large volume printing onto common fabrics such as cotton T-shirt, the cold peel film is a better choice on print complex and fine small patterns onto special material such as tarpaulin, coated cloth, canvas and flannelette.